Temporary Works Engineering

- Trusted Construction Experts in Melbourne

Temporary Works Engineering Services

Temporary Works Engineering involves the method of producing concrete elements off-site in a controlled, optimal environment, typically within a precast concrete manufacturing plant. In this process, reinforcement is placed into reusable and adjustable moulds, followed by the pouring, vibrating, and curing of concrete. Depending on the requirements, architectural finishes such as formliner patterns, honing, polishing, or staining can be applied either pre-pour or post-pour while the concrete elements remain in the factory.

Once the necessary steps are completed, the precast concrete elements are safely transported to the construction site for erection. Precast products are commonly used in building construction, civil engineering, and landscaping applications. The use of precast concrete saves time and labor costs while offering a more uniform casting and greater design flexibility. For projects exposed to unpredictable weather and extreme environmental factors, precast concrete provides an efficient, reliable solution.

Temporary Works Design

Temporary Works Engineering Design is essential for the safe handling and installation of precast concrete elements during the construction phase before they become part of the permanent structure. Our comprehensive services include:

- Lifting, Temporary Bracing, Transport, and Storage Design of precast concrete elements

- Temporary Footing Design for bracing precast elements during construction.

- Formwork and Falsework Design to support construction activities.

- Crane Lift Studies to ensure safe lifting operations.

- Backpropping Designs for the construction stage to support the structure during assembly.

- Excavation Support Designs and Protection Works to safeguard both the site and workers.

Our expert team works closely with you to deliver safe, reliable, and efficient temporary works designs tailored to your project’s needs, ensuring smooth and secure construction operations.

Precast Lifting and Bracing Designs

FR Engineering’s engineering team can analyze the precast elements for the stresses developed during various stages of handling and ensure the structural integrity of the element is not compromised. We will design and certify the components cast into the element to be used at temporary stages such as lifting and bracing. Providing conventional and case-specific bracing solutions for precast elements is one of the skills our team excels at. Before commencing our designs, we work closely with you and consider all on-site equipment to ensure that our designs are suitable for your circumstances.

Concrete Panel Sequencing

At FR Engineering, our team has experience providing efficient, cost-effective, and safe installation sequences for concrete panels across many different sites with unique needs. Sequencing will ensure a smooth workflow and safety for all personnel involved in the process while achieving savings in cost and time.

Crane Placement and Erection Design

At FR Engineering, our engineering team can determine the safest and most effective location to place the cranes, taking multiple factors into consideration, such as the types of lifts available, the weights and sizes of the precast elements, and the pickup locations. These factors play a crucial role in determining which size and type of crane is best suited for your particular need. Every site is unique, and we always treat them as such during the planning and design stages.

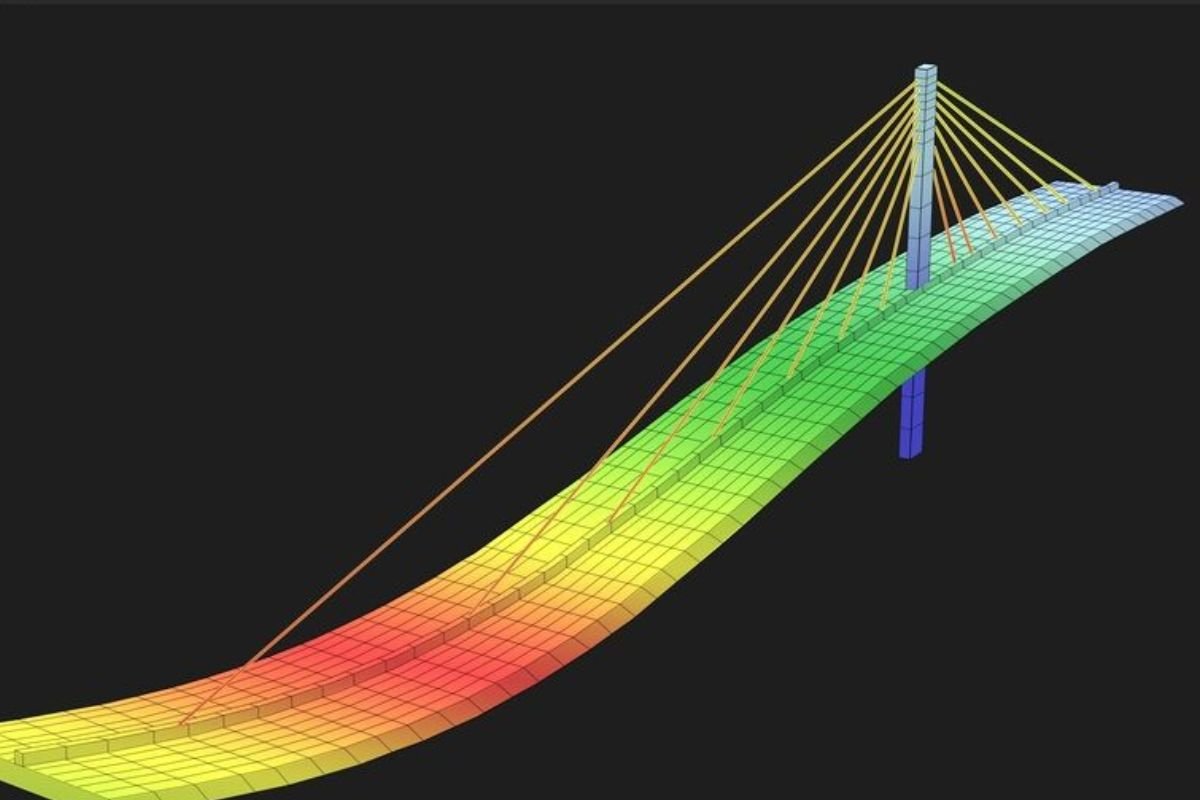

Stress Analysis

At FR Engineering, our team can provide Finite Element Analysis (FEA) design to monitor the stresses of the precast element under load. This method allows us to optimize the structural design of your precast elements, ensuring they are safe for your application while avoiding any costly or unnecessary over-engineering.

Multi-Storey Core Design

At FR Engineering, our team has extensive experience redesigning the cores of multi-storey buildings, from in-situ developments to precast structures. We understand the critical considerations involved, such as the in-place cost of connections. Our expertise allows us to optimize the placement sequence for elements like precast stairs and landings, ensuring the entire construction process progresses as smoothly and efficiently as possible.

Design, Construction and Inspection Services

At FR Engineering, our team of highly skilled engineers collaborates closely with clients throughout the design process to ensure effective communication, minimizing delays and reducing costs.

We utilize state-of-the-art structural analysis tools to deliver designs that are not only accurate but also tailored to meet your specific requirements. Our team is capable of efficiently handling a diverse range of commercial precast structure designs, ensuring the best possible outcome for your project.

Our Erection Design Engineers are also available for on-site inspections of temporary precast works at short notice. This includes, but is not limited to:

- Propping

- Lifting and bracing

- Prop removal

With in-depth knowledge of Australian standards for precast concrete design (AS3850, AS4671, AS3600, and AS5216), our inspection engineers can provide certification that meets these rigorous requirements. We pride ourselves on our flexibility and can meet you on-site to deliver expert advice when needed.

Our Erection Design Engineering team works seamlessly with Shop Detailers and Structural Design Engineers to ensure smooth coordination for industrial and warehouse building designs. We also offer comprehensive civil, hydraulic, and traffic engineering services as part of our holistic approach.